Avoiding Mistakes in Industrial Batteries Care

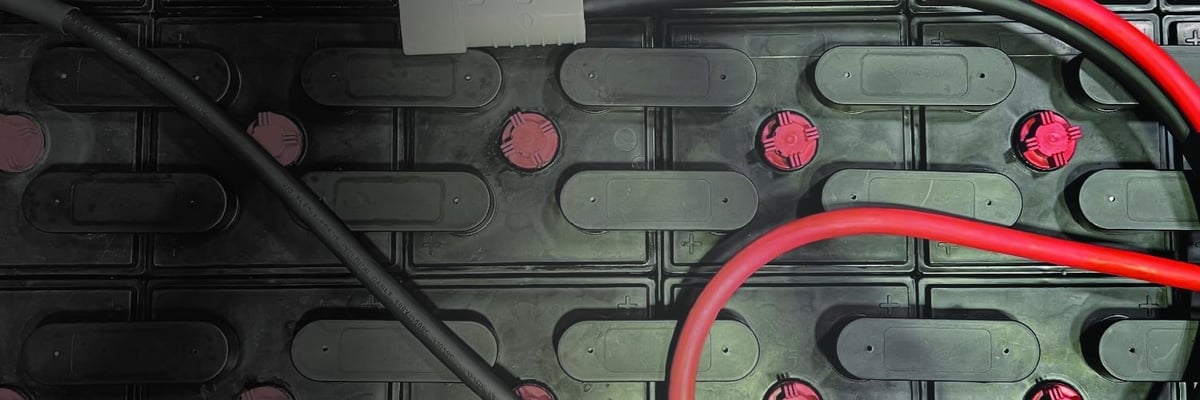

In the world of industrial operations, the efficiency and reliability of equipment often hinge on the performance of batteries. Whether it's forklift batteries or other types, understanding how to care for these power sources is paramount. Neglecting proper maintenance can not only lead to operational inefficiencies but can also significantly shorten the lifespan of your batteries. In this article, we will delve into common pitfalls in battery care and provide actionable insights on how to avoid them.

Avoiding Mistakes in Industrial Batteries Care

When it comes to industrial batteries, avoiding mistakes in their care is essential for maximizing performance and longevity. Here’s a closer look at some prevalent errors and how you can sidestep them.

1. Overcharging: The Silent Battery Killer

One of the most significant mistakes made in industrial battery care is overcharging. While it might seem harmless to leave your forklift batteries plugged 24 volt flat plate forklift batteries in for extended periods, this practice can lead to severe damage over time.

-

Why Is Overcharging Harmful? Overcharging leads to excessive heat generation within the battery, which can cause internal components to break down. The electrolyte solution may also evaporate, leading to reduced performance and potentially catastrophic failure.

-

How Can You Avoid Overcharging? To prevent overcharging, invest in advanced charging systems that feature automatic shut-off mechanisms. These systems can intelligently monitor charge levels and disconnect once optimal voltage is reached.

-

Keep an Eye on Charging Cycles Regularly check charging cycles against manufacturer recommendations. Most suppliers provide guidelines that indicate how long batteries should be charged based on usage patterns.

2. Ignoring Battery Maintenance Schedules

Another common mistake is neglecting regular maintenance schedules for forklift batteries. Just like any other piece of machinery, batteries require routine checks and servicing.

-

What Should a Maintenance Schedule Include? A comprehensive maintenance schedule should cover:

-

Visual inspections for physical damage

-

Checking electrolyte levels

-

Cleaning terminals to prevent corrosion

-

Testing battery health using diagnostic tools

-

Why Is This Important? Regular maintenance not only keeps your batteries running optimally but also helps identify potential issues before they escalate into costly repairs or replacements.

-

Tips for Effective Maintenance Create a calendar reminder for routine checks, and ensure all relevant staff members are trained on proper maintenance procedures. Keeping records of maintenance activities can also prove beneficial for tracking battery performance over time.

Key Considerations in Forklift Battery Care

Taking care of forklift batteries involves more than just avoiding mistakes; it requires an understanding of key considerations that impact their functionality and lifespan.

1. Temperature Control

Did you know that temperature has a direct effect on battery performance? Both extreme heat and cold can adversely affect battery efficiency.

-

Optimal Operating Temperatures Most industrial batteries operate best within a temperature range of approximately 20°C to 25°C (68°F to 77°F). Deviating from this range can reduce capacity significantly.

-

How Can You Manage Temperature? If possible, store your forklift batteries in climate-controlled environments where temperatures remain stable. If outdoor storage is necessary, consider insulating solutions or protective covers designed to mitigate extreme temperature fluctuations.

2. Proper Storage Practices

When not in use, how you store your batteries matters considerably as well. Improper storage conditions can lead to self-discharge or even physical damage over time.

- Storage Tips:

- Store batteries upright in a dry location.

- Ensure they are fully charged before storage.

- Protect them from moisture and corrosive substances.

- Periodically check stored batteries for voltage levels and overall condition.

By following these practices, you’ll enhance the life expectancy of your forklift batteries while ensuring they’re ready when you need them most!

FAQs About Avoiding Mistakes in Industrial Batteries Care

Q1: How often should I perform maintenance on my industrial forklift batteries?

A1: It's recommended to conduct maintenance every month or after every major usage cycle, whichever comes first, ensuring all components are functioning correctly.

Q2: What are the signs that my forklift battery needs replacement?

A2: Common signs include decreased runtime, swelling or leakage from the casing, and visible corrosion around terminals.

Q3: Can I use any charger with my forklift battery?

A3: No! Always use chargers specifically designed for your battery type to avoid overcharging or undercharging issues that could lead to failure.

Q4: What happens if I let my forklift battery completely discharge?

A4: Allowing complete discharge can cause irreversible damage and reduce the overall capacity of the battery significantly.

Q5: Are there any benefits to using lithium-ion forklift batteries instead of traditional lead-acid ones?

A5: Yes! Lithium-ion batteries typically offer faster charging times, longer lifespans, lighter weight, and higher energy density compared to lead-acid options.

Q6: What’s the best way to clean my forklift battery terminals?

A6: Use a mixture of baking soda and water with a soft brush to clean corrosion off terminals gently; remember always to wear protective gear!

Conclusion

In summary, avoiding mistakes in industrial battery care—especially concerning forklift batteries—can profoundly impact equipment efficiency and lifespan. By being mindful about overcharging, adhering strictly to maintenance schedules, monitoring temperature conditions closely, and practicing proper storage techniques, businesses can optimize their operations while extending the life of their vital power sources.

Remember that knowledge is power! The more informed you are about your industrial battery's needs and behaviors, the less likely you'll run into problems down the line. So take action today—implement these strategies—and watch as your equipment performs at its peak!