Cost Savings with Efficient Industrial Batteries

Introduction

In today's fast-paced industrial landscape, the quest for cost savings is more critical than ever. Companies are continually seeking ways to maximize their operational efficiency while minimizing expenses. One often-overlooked area where significant savings can be realized is in the use of efficient industrial batteries. These power sources are not just vital for running machinery; they can dramatically impact a company's bottom line. In this article, we will delve into how investing in efficient industrial batteries—specifically forklift batteries—can lead to substantial cost savings, improved productivity, and enhanced sustainability.

Cost Savings with Efficient Industrial Batteries

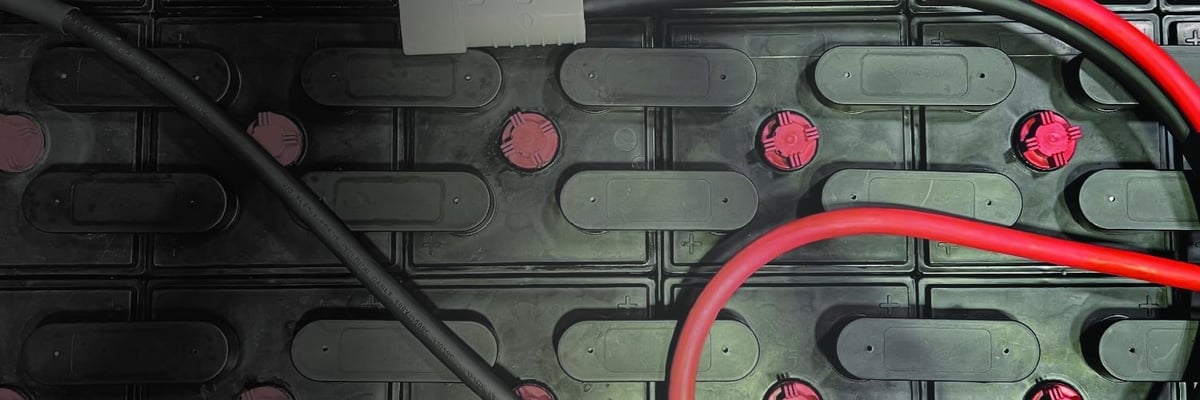

When it comes to the operational backbone of many industries, efficient industrial batteries play a crucial role. They provide the necessary energy to power machines like forklifts, pallet jacks, and other material handling equipment. But how do these batteries contribute to cost savings? Let's break it down.

1. Extended Battery Life

One of the primary benefits of modern industrial batteries is their extended lifespan compared to older models. Traditional lead-acid forklift batteries typically last around 1,500 cycles, while newer lithium-ion options can exceed 5,000 cycles without significant degradation in performance. This extended life means fewer replacements over time.

- Cost Implications: The initial investment may be higher for lithium-ion batteries, but the longevity significantly offsets that expense. Companies can save on both battery purchase costs and labor associated with frequent replacements.

2. Reduced Energy Costs

Efficient industrial batteries are designed to optimize energy usage. For instance, lithium-ion forklift 80 volt flat plate forklift batteries batteries can charge faster and operate longer than conventional options. This increased efficiency translates to reduced energy consumption during charging cycles.

- Energy Efficiency Table:

| Battery Type | Average Charge Time | Average Cycle Life | Energy Consumption | |-------------------|---------------------|--------------------|--------------------| | Lead-Acid | 8-12 hours | 1,500 cycles | High | | Lithium-Ion | 1-3 hours | 5,000 cycles | Low |

This table clearly shows that while lead-acid batteries take a long time to charge and have a shorter lifespan, lithium-ion alternatives offer quicker charging times and greater 36 volt flat plate forklift batteries cycle longevity.

3. Lower Maintenance Costs

Another area where companies can achieve cost savings is through reduced maintenance requirements associated with modern battery technologies. Traditional lead-acid forklift batteries require regular watering and maintenance checks to ensure optimal performance.

- Maintenance Tasks:

- Watering every few weeks

- Regular cleaning

- Checking electrolyte levels

In contrast, lithium-ion forklift batteries are virtually maintenance-free; they don’t need watering or regular checks for electrolyte levels.

- Savings Breakdown:

- Labor costs related to maintenance tasks

- Reduced downtime for machinery resulting from fewer maintenance needs

This reduction in upkeep not only saves money but also allows employees to focus on more productive tasks rather than routine maintenance checks.

4. Increased Productivity

Time is money in any industry. If your machinery isn’t running efficiently due to battery-related issues or inefficiencies, that translates directly into lost revenue opportunities.

Efficient industrial batteries help streamline operations by providing consistent power without interruption:

- Key Benefits:

- Faster charging times mean less downtime.

- Longer-lasting energy means fewer interruptions.

Companies using efficient forklift batteries often report increased operational throughput due to fewer delays linked to battery failures or recharging requirements.

Sustainability: A Hidden Cost Saving?

When discussing cost savings related to efficient industrial batteries, 12 volt flat plate forklift batteries one aspect often overlooked is sustainability. In today’s eco-conscious market, companies that prioritize green practices can enjoy additional financial benefits:

1. Decreased Environmental Impact

Using advanced battery technologies reduces waste associated with battery disposal and replacement:

- Proper recycling programs for lithium-ion batteries lower environmental burdens.

- Companies that adopt sustainable practices may qualify for tax incentives or grants aimed at reducing carbon footprints.

2. Enhanced Corporate Image

Emphasizing sustainability can enhance brand reputation in a competitive market:

- Customers increasingly prefer businesses that demonstrate environmental responsibility.

Investing in efficient industrial batteries thus serves as both an operational improvement and a marketing strategy—a win-win situation!

FAQs about Cost Savings with Efficient Industrial Batteries

Q1: How do I choose the right battery for my operation?

To select the appropriate battery type—whether traditional lead-acid or modern lithium-ion—assess your specific operational needs including runtime requirements and frequency of use.

Q2: What are some signs that it's time to replace my forklift battery?

Common indicators include diminished run times, frequent need for recharges before completing work shifts, or visible damage such as swelling or leaking fluid.

Q3: Are lithium-ion forklift batteries worth the initial investment?

Yes! While upfront costs may be higher than traditional options, the long-term savings from durability and efficiency make them a worthwhile investment.

Q4: Can I retrofit my existing equipment with new battery technology?

In many cases yes! However, consult with your equipment manufacturer or supplier first for compatibility assessments before making changes.

Q5: What are some best practices for maintaining industrial batteries?

Even though modern options require less maintenance than traditional types, implementing standard checks (e.g., ensuring terminals are clean) helps prolong lifespan further.

Q6: Do efficient forklift batteries really improve safety?

Absolutely! Consistent power supply provides predictable operation conditions which enhance overall workplace safety by reducing unexpected shutdowns or malfunctions during use.

Conclusion

Cost savings with efficient industrial batteries aren't just about slashing expenses; they encompass several layers of operational enhancements—from extending battery life and reducing energy costs to increasing productivity and promoting sustainability practices that resonate well within modern business ethics.

By investing wisely in advanced technologies like lithium-ion forklift batteries rather than sticking solely with outdated models, companies position themselves not only forklift batteries for immediate savings but also long-term success in an increasingly competitive environment focused on efficiency and innovation.

So when considering your next battery purchase or upgrade—remember: Choosing wisely could pay off handsomely in both dollars saved and improvements made!