Expected Lifespan of Lead Acid Forklift Batteries

When it comes to the efficiency and effectiveness of warehouse operations, the type and condition of forklift batteries can make a massive difference. Particularly, lead acid forklift batteries have been a staple in the industry for decades. Understanding their expected lifespan is crucial for businesses looking to optimize performance and minimize costs. In this article, we’ll delve deep into the life expectancy of lead acid forklift batteries, factors influencing their longevity, maintenance tips, and frequently asked questions.

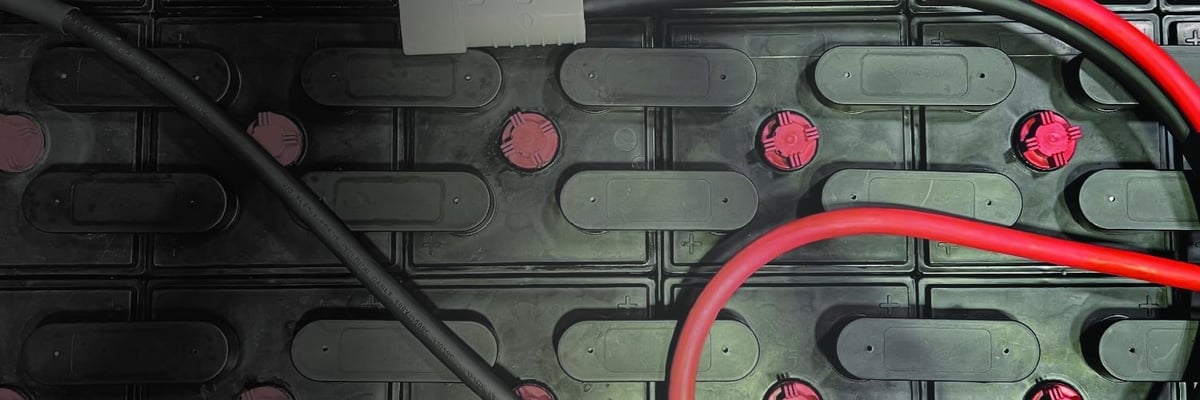

Expected Lifespan of Lead Acid Forklift Batteries

Lead acid forklift batteries typically have an expected lifespan ranging from 3 to 5 years, depending on various factors such as usage patterns, maintenance practices, and environmental conditions. While this range gives a general idea, it’s essential to understand what can affect this lifespan significantly.

Factors Influencing Lifespan

- The deeper the discharge of the battery before recharging, the shorter its overall lifespan will be. Regularly discharging your battery below 50% can lead to premature degradation.

- Each time a battery goes through a charge cycle (discharging and recharging), it contributes to its wear and tear. On average, lead acid batteries can endure around 1,500 charge cycles under optimal conditions.

- Extreme temperatures—both hot and cold—can adversely affect battery performance. High temperatures can accelerate corrosion of internal components while low temperatures may reduce the battery's capacity.

- Proper maintenance is critical for prolonging battery life. Regular cleaning, fluid level checks, and equalizing charges can enhance longevity significantly.

- How often and how intensively forklifts are used directly impacts battery life. Continuous high-intensity usage may lead to faster deterioration compared to more moderate use.

Understanding Battery Capacity

The capacity of a battery is another vital aspect that impacts its lifespan and performance. Measured in amp-hours (Ah), this figure indicates how much energy a battery can store. As batteries age, their capacity diminishes due to factors like sulfation—a process where sulfate crystals form on the lead plates inside the battery during discharging but fail to fully dissolve during charging.

A well-maintained lead acid forklift battery might start with a capacity rating but could lose up to 20% or more over its lifetime if proper care isn’t taken.

Maintenance Tips for Extending Battery Life

To maximize the expected lifespan of lead acid forklift batteries, businesses should consider implementing 80 volt flat plate forklift batteries several best practices:

Regular Inspections

- Schedule routine inspections every few months to check for signs of wear or damage.

- Look for any leaks or corrosion around terminals that might indicate underlying issues.

Proper Charging Techniques

- Always recharge your batteries after they’ve discharged to about 30-50%. Avoid complete discharges whenever possible.

- Use an automatic charger that stops charging once the battery reaches full capacity to prevent overcharging.

Watering Practices

- Maintain proper water levels in flooded lead-acid batteries by topping them off with distilled water after charging.

- This helps prevent overheating and extends overall life by reducing damage caused by low electrolyte levels.

Temperature Management

- Keep your batteries stored in environments with controlled temperatures as much as possible.

- Avoid placing them in areas subject to extreme heat or cold fluctuations which could impact performance dramatically.

Training Staff

- Ensure that personnel operating forklifts understand how to care for and maintain the batteries properly.

- Provide training on recognizing potential issues early on before they become significant problems.

Comparison: Lead Acid vs Other Types of Forklift Batteries

While lead acid batteries are widely used due to their initial lower cost and established technology, there are alternative options available as well:

| Type | Expected Lifespan | Initial Cost | Maintenance Needs | |--------------------|-------------------|------------------|----------------------------------------| | Lead Acid | 3-5 years | Lower 18 volt flat plate forklift batteries | Requires regular watering & maintenance | | Lithium-Ion | Up to 10 years | Higher | Minimal; no watering required | | Nickel Cadmium | 2-7 years | Moderate | Requires special disposal considerations |

Lithium-ion batteries stand out with significantly longer lifespans while also requiring less maintenance—however they come at a higher initial investment cost. On the other hand, nickel-cadmium has shorter lifespans but offers robust performance metrics under varying conditions.

FAQs about Expected Lifespan of Lead Acid Forklift Batteries

1. What can I do if my forklift’s battery isn’t holding a charge?

If you notice a decline in your battery's ability to hold a charge, first check if there’s sufficient water level or any visible corrosion on terminals. If everything appears normal yet you experience issues, consider having it tested professionally as it may need replacement sooner than expected.

2. How often should I water my lead acid forklift batteries?

Water should generally be added every month; however this could vary based on usage frequency and environmental conditions affecting evaporation rates—monitor closely during periods of heavy use or high temperature!

3. Is there any way to revive an old forklift battery?

In some cases where sulfation has occurred but not severely damaged cells yet still shows some usable capacity—you might try desulfation techniques with specialized chargers designed for that purpose! However results aren't guaranteed—sometimes replacement is best!

4. Are there specific signs indicating my forklift battery needs replacement?

Yes! Signs include reduced run time despite being fully charged; frequent overheating during use; visible physical damage like swelling or leaks; these all indicate it's time for new equipment!

5. Can I mix different brands or types of forklift batteries?

Mixing different brands/types isn't advisable due differing chemistries leading uneven discharge rates resulting premature failure across all units involved! Stick with compatible brands/models recommended by manufacturer guidelines instead!

6. How does temperature affect my forklift's performance?

High ambient temperatures can drastically shorten your amp-hour rating while low temps may reduce effective load handling capabilities—all leading operational inefficiencies impacting productivity overall!

In conclusion, understanding the expected lifespan of lead acid forklift batteries is pivotal for any business relying on material handling equipment in warehouses or industrial environments. With proper care and attention paid toward maintenance practices outlined above coupled alongside knowledge surrounding usage patterns influencing longevity—it’s entirely possible extend these powerful workhorses beyond just their typical life expectancy thresholds!