Forklift Batteries Maintenance Schedule

In the fast-paced world of warehouse management and logistics, maintaining your fleet of forklifts is an essential aspect that can’t be overlooked. One of the most crucial components of any forklift is its battery. The efficiency, longevity, and overall performance of your forklift batteries forklifts often hinge on the health of their batteries. This article aims to provide a comprehensive Forklift Batteries Maintenance Schedule that will ensure your batteries remain in optimal condition, thus enhancing the lifespan of your equipment.

Understanding Forklift Batteries

What are Forklift Batteries?

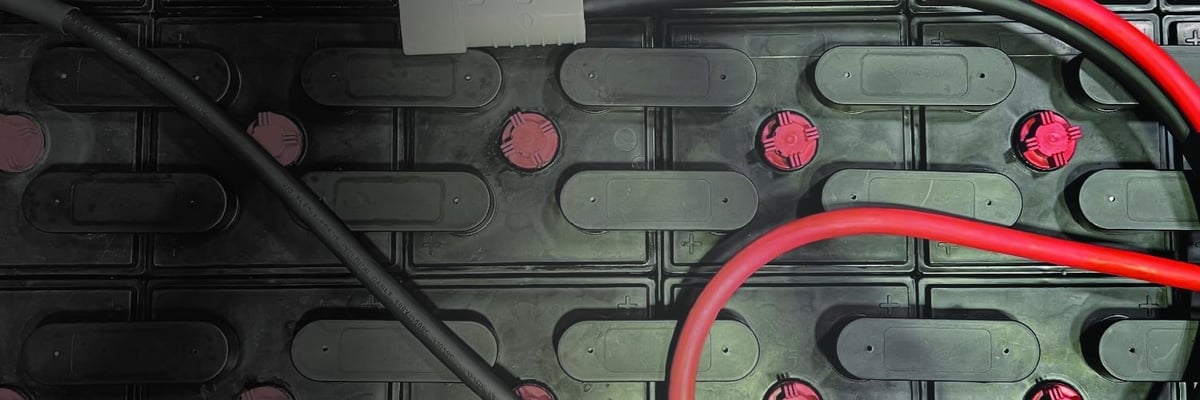

Forklift batteries are large, rechargeable power sources typically used in electric forklifts. Unlike standard batteries you might find in cars or household appliances, forklift batteries are designed to deliver high currents over extended periods. They’re usually classified into two main types: lead-acid and lithium-ion.

Types of Forklift Batteries: A Comparative Analysis

| Type | Pros | Cons | |--------------------|-------------------------------------|----------------------------------------| | Lead-Acid | Cost-effective; widely available | Heavier; requires regular maintenance | | Lithium-Ion | Lightweight; faster charging | Higher initial cost; limited lifespan |

Understanding these differences can help you make informed decisions when choosing a battery for your forklift fleet.

The Importance of Regular Maintenance

Why Maintain Your Forklift Batteries?

Regular maintenance 80 volt flat plate forklift batteries of forklift batteries is paramount for several reasons:

How Does Poor Maintenance Affect Performance?

Neglecting battery maintenance can lead to sulfation, which reduces capacity and performance. Over time, this can result in shorter operating times and increased charging cycles, further exacerbating wear and tear.

Forklift Batteries Maintenance Schedule

Establishing a systematic maintenance schedule for your forklift batteries is crucial for maximizing their lifespan and efficiency. Here’s a breakdown:

Daily Checks

-

Visual Inspection

-

Check for any signs of physical damage or corrosion.

-

Water Levels

-

Ensure water levels are adequate in flooded lead-acid batteries.

-

Cleanliness

-

Keep terminals clean from dust and debris.

Weekly Maintenance Tasks

-

Check Voltage

-

Use a voltmeter to ensure proper voltage levels.

-

Electrolyte Levels

-

Inspect electrolyte levels weekly; top off with distilled water as needed.

Monthly Procedures

-

Conduct a Load Test

-

Assess battery capacity under load conditions.

-

Inspect Connections

-

Tighten all connections to prevent electrical resistance.

Quarterly Actions

-

Deep Cleaning

-

Clean the entire battery compartment thoroughly.

-

Professional Inspection

-

Arrange for professional servicing to evaluate overall health.

Annual Review

- Conduct a comprehensive assessment including:

- Battery age

- Performance metrics

- Replacement planning

Common Issues Faced with Forklift Batteries

What Are the Signs Your Battery Needs Attention?

Being proactive about these issues can save you considerable time and money down the line.

How to Diagnose Common Forklift Battery Problems?

Symptoms & Solutions Table

| Symptom | Possible Cause | Recommended Action | |---------------------------|------------------------------------|------------------------------------------| | Slow charging | Sulfation | Desulfation treatment | | Overheating | Overcharging | Adjust charging settings | | Reduced lift capacity | Internal damage | Replace battery |

Best Practices for Charging Forklift Batteries

Charging Procedures: Do's and Don’ts

Do:

- Charge after each shift.

- Use appropriate chargers designed for your specific battery type.

Don’t:

- Let the battery deplete below 20%.

- Overcharge as it can cause overheating.

Optimal Charging Environment

Ensure that the charging area is well ventilated to avoid gas buildup, especially when charging lead-acid batteries that emit hydrogen gas during charging cycles.

Storage Tips for Forklift Batteries

How Should You Store Unused Forklift Batteries?

Safety Protocols When Handling Forklift Batteries

Why is Safety Important?

Working with heavy machinery like forklifts involves potential hazards related to battery handling such as acid spills or electrical shocks.

Safety Checklist

FAQ Section

What is the average lifespan of forklift batteries?

The average lifespan varies depending on usage but generally ranges from five to seven years for lead-acid batteries while lithium-ion can last up to ten years or more with proper care.

How often should I perform maintenance on my forklift batteries?

A daily visual check alongside weekly inspections is recommended, while more detailed examinations should occur monthly or quarterly based on usage patterns.

Can I use tap water in my lead-acid forklift batteries?

No! It’s important to use distilled water only as tap water may contain minerals that could harm the battery over time.

What should I do if my forklift battery overheats?

First, stop using it immediately! Allow it some time to cool down before inspecting it further, looking for signs of damage or faults in connections or chargers used.

Are lithium-ion forklift batteries worth the investment?

Absolutely! While they come at a higher initial cost, their longer lifespan and reduced maintenance needs often offset this expense over time.

How do I know if my forklift battery needs replacing?

Signs include frequent recharging requirements, visible swelling or leakage around terminals, or diminished lift capacity during operation—these all indicate potential issues necessitating replacement soon!

Conclusion

Maintaining fork-lift batteries isn't just about performing routine checks—it's about nurturing your investment so that it pays dividends in productivity and longevity! Whether you're managing a large warehouse operation or simply utilizing forklifts occasionally within smaller setups—the principles outlined above will serve as invaluable guidelines toward fostering an efficient work environment while ensuring safety measures remain paramount throughout operations involving heavy machinery like our trusty friend—the fork-lift!

Through consistent application of this comprehensive Forklift Batteries Maintenance Schedule, not only do you enhance operational efficiency but also extend your fleet's durability—a true win-win situation indeed!