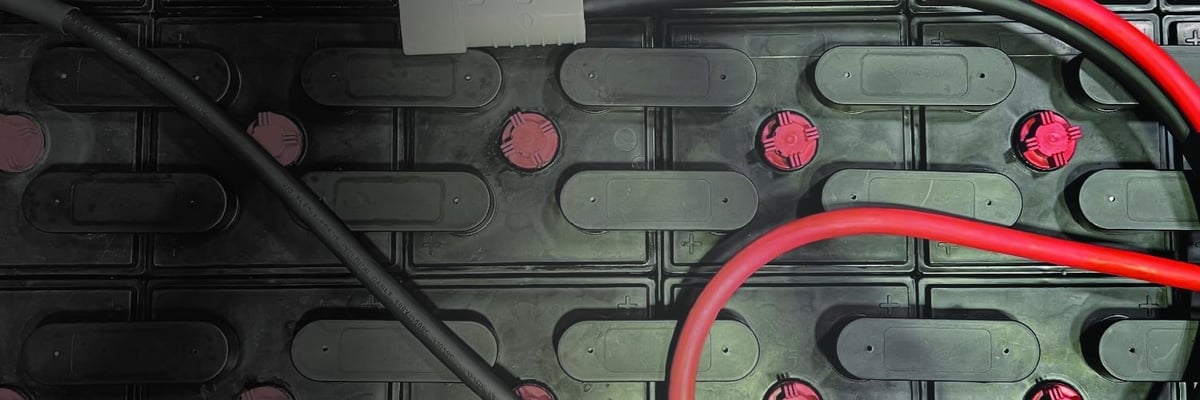

Proper Watering of Lead Acid Forklift Batteries

Maintaining a forklift’s efficient operation relies heavily on the proper maintenance of its lead-acid batteries. These batteries play a critical role in powering your forklift, and neglecting their upkeep can lead to reduced performance and premature failure. One of the most vital aspects of battery maintenance is proper watering. In this article, we’ll explore the ins and outs of watering lead-acid forklift batteries, ensuring that you maximize their lifespan and efficiency.

Proper Watering of Lead Acid Forklift Batteries: The Basics

Lead-acid forklift batteries require regular watering to maintain optimal performance. But what does that mean? Simply put, watering involves adding distilled water to the battery cells to replace the electrolyte that gets depleted during use.

Why Is Proper Watering Important?

The importance of proper watering cannot be overstated. Here are some reasons why:

Prevents Damage: When a battery cell runs low on electrolyte, it can cause irreversible damage to the plates inside. This can significantly shorten the lifespan of your forklift batteries.

Improves Efficiency: A well-watered battery operates more efficiently, providing consistent power output for extended periods. This means less downtime and increased productivity at your workplace.

Reduces Maintenance Costs: Regularly maintaining your batteries through proper watering may prevent costly repairs or replacements in the long run.

How Often Should You Water Your Forklift Batteries?

The frequency of watering depends on several factors such as usage patterns, environmental conditions, and temperature. Generally speaking:

- Daily Use: If you’re using your forklifts daily for several hours, check the water level once a week.

- Intensive Use: For heavy-duty applications, consider checking every few days.

- Seasonal Changes: Hotter weather tends to evaporate water faster; thus, monitor more frequently during summer months.

Best Practices for Proper Watering of Lead Acid Forklift Batteries

Now that we understand the importance and frequency of watering, let’s dive into some best practices to ensure you’re doing it right.

Step-by-Step Guide to Watering Your Forklift Batteries

Safety First: Always wear protective gear—gloves, goggles, and an apron—when handling batteries.

Inspect Battery Condition: Before adding water, check for any signs of damage or leaks. If you notice anything unusual, consult with a technician before proceeding.

Use Distilled Water: Regular tap water contains minerals that can harm battery performance over time. Stick with distilled water for optimal results.

Fill to Appropriate Level: Remove the vent caps carefully and fill each cell with distilled water until it reaches just below the bottom of the fill tube or mark within each cell.

Replace Vent Caps Securely: Ensure all vent caps are replaced properly after watering to avoid spills or contamination.

Clean Up: Wipe down any spilled electrolyte immediately as it can corrode surfaces over time.

Common Mistakes to Avoid When Watering Forklift Batteries

-

Overwatering: Adding too much water can lead to overflow during charging, which can create hazards.

-

Neglecting Regular Checks: Ignoring routine checks may lead to significant issues down the line.

-

Using Contaminated Water: Always opt for distilled water; impurities can lead to sulfation—a process that reduces efficiency.

Understanding Electrolyte Levels in Forklift Batteries

To really grasp the essence of proper watering of lead-acid forklift batteries, it’s essential to understand how electrolyte levels work within these systems.

What Is Electrolyte?

Electrolyte is a mixture primarily composed of sulfuric acid and water in lead-acid batteries responsible for conducting electricity between positive and negative plates during discharging and charging cycles.

How Does Electrolyte Level Affect Battery Life?

When electrolyte levels drop due to evaporation or usage:

-

The active material on battery plates becomes exposed air which leads them to sulfate quickly; thus degrading performance.

-

Low levels may cause overheating during charging cycles leading potentially catastrophic failures or explosions in extreme cases.

Signs That Your Battery Needs Watering

Keep an eye out for these indicators:

- The presence of corrosion around terminals

- Difficulty starting or sluggish operations

- Visible cracks or bulges in battery casing

FAQs About Proper Watering of Lead Acid Forklift Batteries

1. How do I know if my forklift battery needs water?

Check if the electrolyte level is below the recommended mark inside each cell; add distilled water if necessary.

2. Can I use tap water instead of distilled water?

No! Tap water contains minerals that may corrode internal components over time; always use distilled water.

3. What happens if I overwater my forklift battery?

Overwatering can result in overflow during charging cycles creating hazardous situations like acid spills.

4. How often should I check my forklift battery's electrolyte levels?

For regular use, aim for at least once a week; intensive use cases might require checks every few days especially in hot climates.

5. Are there any safety precautions I should take while watering?

Absolutely! Always wear gloves and goggles when handling batteries due to corrosive materials present in 12 volt flat plate forklift batteries electrolytes.

6. Can improper watering damage my forklift battery?

Yes! Neglecting regular checks or using contaminated/non-distilled waters could severely reduce your battery's lifespan and efficiency.

Conclusion

Proper watering of lead acid forklift batteries isn’t just another task on your maintenance checklist—it’s crucial for ensuring longevity and optimal performance from these essential components of your industrial equipment. By adhering closely to best practices outlined here—from using only distilled 24 volt flat plate forklift batteries water to recognizing signs that indicate it's time for more hydration—you not only prolong the life cycle but also enhance overall efficiency within your operations!

In sum, investing time into understanding how best practices affect your equipment will yield dividends far beyond mere numbers on a ledger sheet—this commitment translates directly into productivity gains across your business’s lifeblood operations! Remember this mantra as you engage with these powerful machines: “A well-watered battery is a happy battery!”