Reducing Downtime with Forklift Batteries

Introduction: The Cost of Downtime in Material Handling

In the fast-paced world of material handling, every second counts. Companies that rely on forklifts for transportation and logistics know that downtime can be a costly affair. Whether it’s due to battery failures, charging issues, or maintenance mishaps, unplanned interruptions can severely impact productivity and profitability. In this article, we will delve into the crucial role of forklift batteries in reducing downtime, exploring tips for proper maintenance, selection, and innovative technologies that can keep your operations running smoothly.

Reducing Downtime with Forklift Batteries

Forklift batteries are at the heart of material handling operations. They provide the necessary power to move goods efficiently across warehouses and distribution centers. However, many companies overlook the importance of maintaining these batteries properly. By prioritizing battery care and understanding their impact on forklift performance, businesses can significantly minimize downtime.

Understanding Forklift Battery Types

When it comes to forklift batteries, there are primarily two types: lead-acid batteries and lithium-ion batteries. Each type has its own set of advantages and disadvantages that can affect operational efficiency.

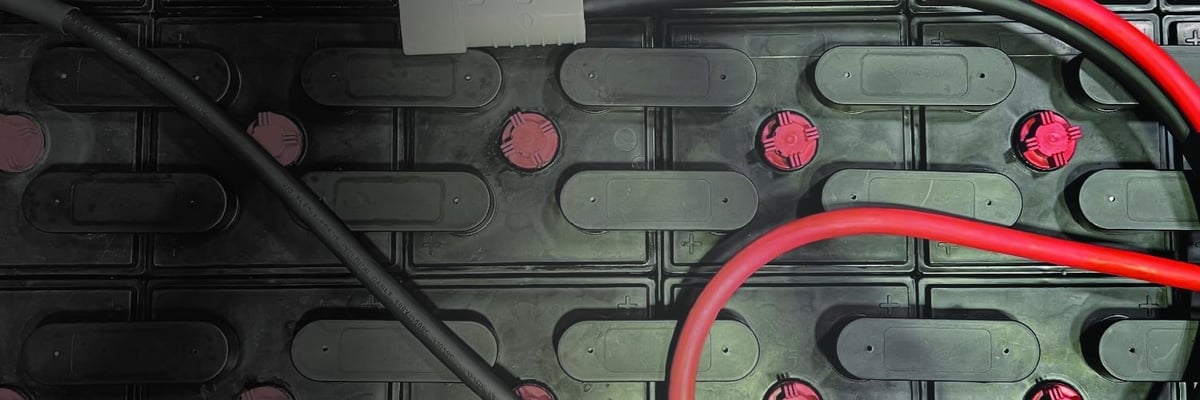

1. Lead-Acid Batteries

Lead-acid batteries are the traditional choice for forklifts. They have been around for decades and are known for their robustness and reliability.

-

Pros:

-

Cost-effective: Lead-acid batteries are generally cheaper to purchase.

-

Established technology: This type is widely understood and supported.

-

Cons:

-

Longer charging times: Typically require several hours to fully charge.

-

Maintenance needs: Regular water checks and equalization charges are essential to prolong lifespan.

2. Lithium-Ion Batteries

Lithium-ion batteries represent a newer technology gaining traction in the forklift industry. They offer several compelling advantages:

-

Pros:

-

Faster charging times: Can be charged in under an hour.

-

Low maintenance: No need for regular watering or equalization charges.

-

Longer lifespan: Generally last longer than lead-acid counterparts.

-

Cons:

-

Higher upfront costs: The initial investment is usually more significant.

-

Limited availability in some forklift models: Not all equipment is compatible with lithium-ion options.

Choosing the Right Battery for Your Needs

When selecting a forklift battery, consider factors such as operational requirements, cost constraints, and maintenance capabilities. Here’s a quick reference table comparing both types:

| Battery Type | Cost | Lifespan | Charging Time | Maintenance Needs | |-------------------|--------|----------|--------------------|-----------------------| | Lead-Acid | Lower | Moderate | 8-12 hours | High | | Lithium-Ion | Higher | Long | Under 1 hour | Low |

By weighing these factors against your specific operational goals, you can make an informed decision that minimizes downtime associated with battery failures or inefficiencies.

Maximizing Efficiency with Proper Battery Maintenance

Once you’ve selected the right type of forklift battery, proper maintenance becomes paramount in ensuring longevity and peak performance.

Regular Inspections

Conducting routine inspections is a vital part of maintaining forklift batteries. Look out for:

- Corrosion on terminals

- Water levels (for lead-acid)

- Physical damage to casing

A good rule of thumb is to inspect your batteries weekly. Catching potential issues early can save you from unexpected breakdowns down the line.

Charging Practices Matter

The way you charge your forklift batteries impacts their lifespan and efficiency:

Avoid Deep Discharge: Try not to let lead-acid batteries discharge below 20% capacity regularly; this practice can drastically shorten their life.

Utilize Smart Chargers: These chargers adjust voltage based on battery needs—helping to extend battery life while reducing downtime during charging periods.

Charge After Every Shift: For maximum efficiency, charge your batteries after each shift instead of waiting until they’re nearly empty.

Don’t Overcharge: Overcharging can generate excessive heat leading to damage; always follow manufacturer guidelines.

Investing in Technology

Technology continues to evolve rapidly within the material handling sector. Consider investing in advanced monitoring systems that track your battery health in real-time:

- These systems provide alerts about charging cycles.

- They analyze usage patterns allowing preemptive actions before problems arise.

As technology improves, so too does our ability to avoid costly downtimes associated with poorly maintained or failing forklift batteries.

FAQ Section

1. What causes forklift battery failure?

Forklift battery failure usually occurs due to improper maintenance practices like deep discharges or neglecting regular inspections leading to corrosion or physical damage.

2. How often should I maintain my forklift batteries?

Routine inspections should occur weekly; however, comprehensive maintenance may be required monthly or quarterly depending on usage intensity and battery type.

3. Are lithium-ion batteries worth the investment?

While lithium-ion batteries have higher upfront costs, their faster charging times, lower maintenance needs, and longer 18 volt flat plate forklift batteries lifespan make them worthwhile investments for many businesses looking to reduce downtime significantly.

4. Can I use a regular charger for my forklift battery?

No! Always use chargers specifically designed for your type of forklift battery (lead-acid or lithium-ion) as they ensure optimal charging without damaging the cells.

5. What is the average lifespan of a forklift battery?

Most lead-acid batteries last around five years with proper care while lithium-ion variants can exceed ten years when maintained correctly.

6. How do I know when my forklift battery needs replacing?

Indicators include reduced performance (lifting power), excessive heat during operation/charging cycles, and physical damages like cracked casings or leaking fluids.

Conclusion: Taking Charge of Your Operations

In conclusion, reducing downtime with forklift batteries hinges on making informed decisions regarding selection, diligent maintenance practices, and embracing technological advancements within material handling operations. Understanding 24 volt flat plate forklift batteries the strengths and limitations of different types of forklifts ensures you maximize productivity while minimizing disruptions caused by faulty power sources.

By investing time into proper care routines—conducting regular inspections as well as utilizing smart chargers—businesses stand poised not only to boost efficiency but also enhance overall workplace safety by preventing accidents linked to equipment failures driven by poor battery management practices.

So remember—when it comes to keeping your forklifts rolling smoothly without interruption—don’t underestimate the significance of those hard-working forklift batteries!