Solving Common Forklift Batteries Problems

Forklifts are an indispensable part of many warehouses and construction sites, helping to move heavy loads efficiently. However, the effectiveness of these machines hinges significantly on their batteries. If you're facing issues with your forklift batteries, you’re not alone. This article dives deep into some common problems associated with forklift batteries and provides practical solutions.

Understanding Forklift Batteries: The Heart of Your Equipment

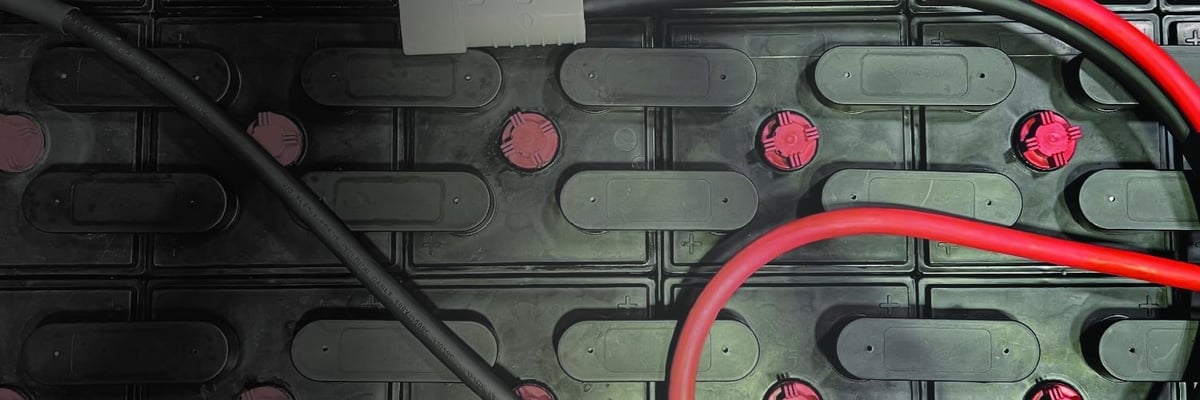

Forklift batteries are typically lead-acid or lithium-ion types, each with its own set of advantages and disadvantages. Understanding how these batteries function can help you troubleshoot common problems effectively.

How Do Forklift Batteries Work?

At a basic level, a forklift battery stores electrical energy that powers the electric motor for lifting and moving loads. The battery undergoes a chemical reaction to generate electricity when charged. Here's a brief overview of how it works:

Understanding this cycle is crucial in diagnosing issues like poor performance or unexpected shutdowns.

Common Types of Problems with Forklift Batteries

Forklift batteries can encounter various issues that hinder performance. Here 80 volt flat plate forklift batteries are some prevalent problems:

- Insufficient Charge: One of the most common complaints is that the forklift does not hold a charge or runs out quickly.

- Overheating: A battery might overheat during operation, which could indicate overcharging or other underlying issues.

- Physical Damage: Cracks or leaks in the battery casing can lead to significant operational hazards.

- Corrosion: Corroded terminals can affect connectivity and overall performance.

- Old Age: Just like any other equipment, forklift batteries have a lifespan beyond which they won’t perform optimally.

By understanding these issues, you can start addressing them one by one.

Solving Common Forklift Batteries Problems

When it comes to troubleshooting forklift batteries, pinpointing the exact issue is half the battle won. Here’s how you 24 volt flat plate forklift batteries can tackle some common problems systematically.

1. Insufficient Charge Issues

If your forklift isn’t holding a charge as it should, here are steps you can take:

-

Check Battery Connections: Loose or corroded connections can cause insufficient power transfer. Make sure all connections are clean and tight.

| Connection Type | Symptoms of Issues | Solutions | |-----------------|--------------------|-----------| | Terminals | Corrosion | Clean with baking soda solution | | Cables | Frayed edges | Replace damaged cables |

-

Examine Charging Equipment: Sometimes the charger itself is at fault. Inspect for any visible damage or wear and check that it's functioning properly using a multimeter.

-

Monitor Usage Patterns: Overuse without adequate charging time can cause excessive wear on your battery. Ensure that your usage aligns with recommended guidelines.

2. Overheating Issues

An overheating battery is not just an inconvenience; it could also pose safety risks. Here’s how to address this problem:

-

Inspect for Overcharging: Use an ammeter to monitor charging rates; if they're consistently high, adjust settings on your charger accordingly.

-

Cooling Periods: Allow the battery to cool down after use before recharging it; continuous heat buildup can degrade battery life significantly.

-

Ventilation Checks: Ensure that there’s adequate ventilation around the charging area to dissipate heat effectively.

3. Physical Damage Troubleshooting

If you notice physical damage such as cracks or leaks in your forklift batteries, immediate action is required:

-

Check for Leaks: A leaking battery can be hazardous due to acid exposure; if found, handle it carefully and consult professionals for proper disposal.

-

Sealing Cracks: Small cracks might be sealed temporarily using specialized adhesive designed for plastics; however, replacement is usually recommended for long-term safety.

4. Addressing Corrosion Issues

Corrosion on terminals can lead to poor conductivity and inefficiency:

-

Regular Cleaning Routine: Establish a routine cleaning schedule using a mixture of baking soda and water to neutralize corrosion.

-

Protective Coatings: After cleaning connections, consider applying petroleum jelly to protect against future corrosion.

FAQs about Forklift Battery Problems

What causes my forklift batteries to lose charge quickly?

Insufficient charging cycles or overuse without adequate downtime often leads to quick charge loss in forklift batteries.

How often should I check my forklift battery's connections?

It's advisable to inspect connections at least once a month as part of regular maintenance checks.

Can I repair physical damage on my forklift battery?

Minor repairs may be possible but replacing severely damaged batteries is generally safer and more effective.

How do I know if my charger is functioning properly?

Using a multimeter will help you check voltage output from your charger; if it's not within specifications, consider getting it serviced.

Are lithium-ion batteries better than lead-acid for forklifts?

Lithium-ion batteries offer quicker charging times and longer lifespan compared to traditional lead-acid options but come at a higher initial cost.

ol2/##

Conclusion

Solving common forklift batteries problems requires an understanding of how these vital components operate along with regular maintenance practices tailored toward preventing issues before they escalate into major headaches. By keeping an eye on symptoms like insufficient 12 volt flat plate forklift batteries charge or overheating—and acting promptly—you’ll ensure that your forklifts remain reliable workhorses in your operation!

Maintaining your investment in quality equipment starts with understanding its core forklift batteries components—like those trusty forklift batteries—so stay proactive!