Tools Needed for Forklift Batteries Maintenance

Maintaining forklift batteries is not just a matter of convenience; it's essential for ensuring the longevity and efficiency of your equipment. The right tools can make all the difference when it comes to keeping your forklift batteries in peak condition. In this article, we’ll dive deep into the Tools Needed for Forklift Batteries Maintenance, exploring everything from basic cleaning supplies to specialized equipment.

Tools Needed for Forklift Batteries Maintenance

Understanding Forklift Battery Types

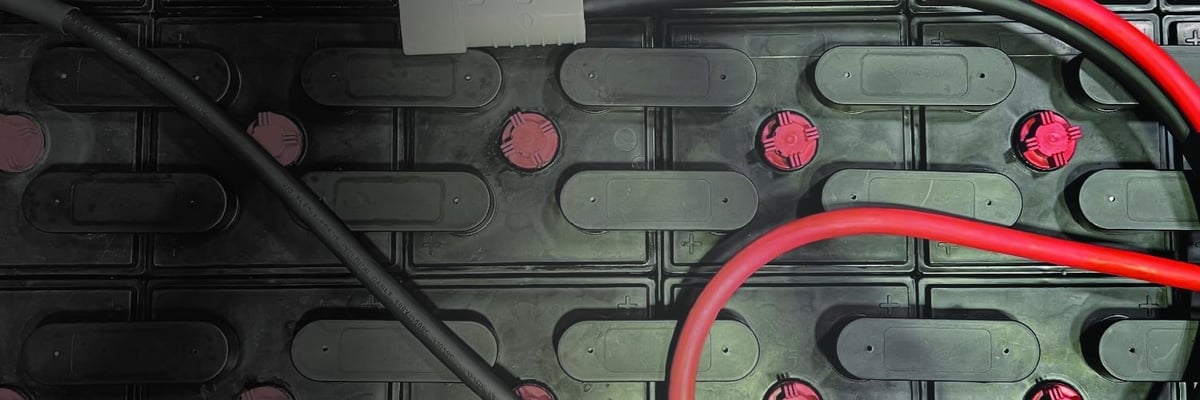

Before delving into the specific tools required, it's crucial to understand the types of forklift batteries you may encounter. Most forklifts are 80 volt flat plate forklift batteries powered by either lead-acid or lithium-ion batteries. Each type has unique maintenance requirements.

-

Lead-Acid Batteries: These are traditional and widely used in forklifts due to their reliability and cost-effectiveness. However, they require regular water checks and equalization charges.

-

Lithium-Ion Batteries: Newer on the market, these batteries are more efficient and require less maintenance. They offer faster charging times but can be more expensive upfront.

Understanding these differences can help you choose the right tools for your specific needs.

Essential Cleaning Tools for Forklift Batteries

When it comes to maintaining forklift batteries, cleanliness is non-negotiable. Dirt and grime can lead to poor performance and 18 volt flat plate forklift batteries even battery failure. Here’s a list of essential cleaning tools to have on hand:

Baking Soda: This common household item can neutralize battery acid spills. Mix it with water to form a paste that can be applied to terminals.

Wire Brushes: A wire brush helps scrub away corrosion from battery terminals effectively. Ensure that you get one specifically designed for battery maintenance.

Safety Goggles and Gloves: Safety should always come first! Protect yourself from harmful chemicals by wearing appropriate gear.

Rags or Absorbent Towels: These are necessary for wiping down surfaces and soaking up excess liquids during maintenance.

Spray Bottle: Fill it with a vinegar solution or baking soda mix for easy application during cleaning.

By having these tools readily available, you'll be well-prepared to keep your forklift batteries clean and functional.

Measurement Instruments for Forklift Batteries

Monitoring battery health is vital in extending its lifespan. Here are some measurement instruments that every warehouse should have:

Hydrometer: This tool measures the specific gravity of the electrolyte solution in lead-acid batteries, giving insight into their charge state.

Voltmeter: Use this device to check voltage levels across individual cells in the battery pack, helping identify weak cells that may need replacement.

Temperature Gun: Overheating can be a sign of trouble in forklift batteries; a temperature gun allows you to monitor heat levels without physical contact.

Battery Analyzer: An advanced tool that provides detailed information about battery health, capacity, and cycle life.

By employing these measurement instruments regularly, you can catch potential issues before they escalate into costly repairs or replacements.

Specialized Equipment for Forklift Battery Maintenance

For more extensive operations, specialized equipment could enhance your forklift battery maintenance routine:

Battery Watering System: This system simplifies adding distilled water to lead-acid batteries while preventing overfilling—a common mistake that leads to damage.

Forklift Battery Lifter/Hoist: If you're dealing with heavy-duty batteries, a lifter makes it safer and easier to handle them during inspection or replacement.

Battery Charger with Equalization Capability: Having an appropriate charger ensures optimal performance through proper charging cycles tailored for each battery type.

Investing in specialized equipment not only enhances safety but also streamlines maintenance efforts significantly.

FAQs About Tools Needed for Forklift Batteries Maintenance

What type of gloves should I use while maintaining forklift batteries?

Using acid-resistant rubber gloves is ideal when handling forklift batteries since they provide excellent protection against corrosive materials often found in lead-acid solutions.

How often should I clean my forklift batteries?

Cleaning should ideally be performed every month or sooner if you notice buildup around terminals or connections—keeping them clean promotes better performance!

Is it safe to use tap water for lead-acid battery maintenance?

No! Always use distilled water when topping off lead-acid batteries as tap water contains minerals that could harm the battery's internal chemistry over time.

Can I perform maintenance on lithium-ion forklifts myself?

While basic cleaning is possible, it's best practice to consult professionals or adhere strictly to manufacturer guidelines regarding lithium-ion systems due to their complexity.

What should I do if I notice corrosion on my battery terminals?

Immediate action is recommended! Disconnect any power sources first before using baking soda mixed with water applied via a wire brush until cleaned thoroughly—ensure everything is dry before reconnecting power!

Are there any specific tools needed only for lithium-ion battery maintenance?

Most standard cleaning tools apply; however, monitoring devices like smart chargers designed specifically for lithium-ion technology will yield better results than traditional options!

Conclusion

In summary, understanding the tools needed for forklift batteries maintenance plays an essential role in ensuring both safety and efficiency in operations involving heavy machinery like forklifts. By equipping yourself with proper cleaning supplies, measurement instruments, and specialized equipment tailored towards your specific battery type—be it lead-acid or lithium-ion—you'll maximize productivity while minimizing risks associated with neglecting this critical aspect of warehouse management! So gear up today; after all, taking care of those forklift batteries means keeping business running smoothly!